In the past when LEDs could only be used as status indicators, the heat dissipation of the package has never been a problem. However, in recent years, the brightness and power of LEDs have been actively improved, and they have begun to be used in backlight and electronic lighting applications. The problem has quietly surfaced. The above statement sounds a bit confusing. Hasn’t it been emphasized today that the brightness breakthrough of 1000w LED grow light? In 2003, Mr. Roland Haitz of Lumileds LighTIng Company derived an empirical technical inference law based on past observations. Starting from the first commercial LED in 1965, during the development of more than 30 years, LED approximately every 18 months The brightness can be doubled in 24 months, and in the next 10 years, it is expected that the brightness can be increased by 20 times, and the cost will be reduced to 1/10 of the existing. This is also the Haitz law that has become popular in recent years. It is considered to be the Moore’s law in the LED industry.

Haitz law in LED field

According to Haitz’s law, LEDs with a brightness of 100lm/W (100 lumens per watt) appeared in 2008; however, the actual development seems to be more advanced than the law. In June 2006, Nichia Chemical Industry (Nichia ) Has begun to provide engineering samples of up to 100lm/W white LED, and is expected to be officially put into mass production by the end of the year.

Haitz’s law can be said to be the Moore’s law in the LED field. According to Roland Haitz, the luminous efficiency of LEDs has doubled almost every 18;24 months for the past 30 years. Therefore, it is estimated that the next 10 years (2003) ; 2013) will increase the brightness by 20 times, but the price will be only 1/10 of the current. Not only the brightness has been continuously improved, but the heat dissipation technology of the LED has also been improved. In 1992, the thermal resistance of an LED was 360°C/W, and then dropped to 125°C/W, 75°C/W, 15°C/W, Now it has reached the point where each LED is 6℃/W~10℃/W. To put it simply, in the past, for every 1 watt of electric energy consumed by LEDs, the temperature would increase by 360℃. Increase by 6℃~10℃.

Haitz’s law can be said to be the Moore’s law in the LED field. According to Roland Haitz, the luminous efficiency of LEDs has doubled almost every 18;24 months for the past 30 years. Therefore, it is estimated that the next 10 years (2003) ; 2013) will increase the brightness by 20 times, but the price will be only 1/10 of the current. Not only the brightness has been continuously improved, but the heat dissipation technology of the LED has also been improved. In 1992, the thermal resistance of an LED was 360°C/W, and then dropped to 125°C/W, 75°C/W, 15°C/W, Now it has reached the point where each LED is 6℃/W~10℃/W. To put it simply, in the past, for every 1 watt of electric energy consumed by LEDs, the temperature would increase by 360℃. Increase by 6℃~10℃.

Fewer particles, high brightness, multiple particles and densely arranged are the culprits of heat increase

Since the brightness efficiency is improved, and the heat dissipation efficiency is improved, isn’t it more contradictory? There should be no heat dissipation problem even more? In fact, it should be more strictly stated that the aggravation of the heat dissipation problem is not in high brightness, but in high power; not in traditional packaging, but in new packaging and new applications.

First of all, in the past, the LED used only as an indicator light, the current of each single light (forward conduction) is mostly 5mA; between 30mA, typically 20mA, and the current high-power LED (Note 1), Each single one will have 330mA; 1A current is sent in, and the “power consumption per one” increases ten times, or even dozens of times (Note 2).

Note 1: In addition to increasing the area of a single light-emitting die, the existing high-power LED practice also implements the practice of packaging multiple dies together. In fact, some white light LEDs put the bare crystals of the three primary colors of red, green, and blue in the same package to mix white light.

Note 2: Although the lighting (forward conduction) voltages of various LEDs are different, this difference is ignored for the time being.

Effect of thermal dispersion on heat dissipation of 1000w led grow LED

In the same single package with a doubled current, the heat will naturally double, so the heat dissipation will of course deteriorate, but unfortunately, because the white light LED is used as the flash of the camera phone, it needs to be used for the small lighting Use light bulbs as the lighting bulbs in the projector, so high brightness is not enough, and high power needs to be used. At this time, heat dissipation becomes a problem.

The above-mentioned LED application method uses only a few high-power LEDs, about 1 to 4 flashes, about 1 to 8 lighting bulbs, and more than 10 in the projector. However, the use of flashes is less and the lighting time is not long. A single light bulb has ample space for heat dissipation around it, and although there is no space for heat dissipation in the projector, a cooling fan can be installed.

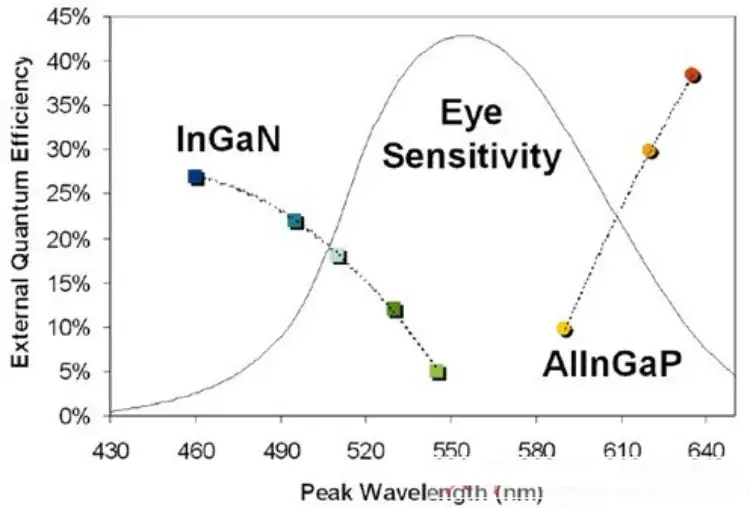

The figure shows the external quantization efficiency diagram of InGaN and AlInGaP LEDs for two kinds of semiconductor materials at each peak wavelength (light color). Although it can be close to 40% under ideal conditions, if the light extraction efficiency is taken into consideration, In fact, they are both 15%; 25%. What’s more, the more efficient parts of the two materials are not in the scope of human eye receptivity, and only 20% below the scope. However, there are still many applications that require high brightness, but need to use grow light LED in a dense arrangement, such as traffic sign lights, revolving lights for information billboards, TV walls made up of LED groups, etc., the result of dense arrangement It is not easy to dissipate heat, which is a heat dissipation problem caused by the application. What’s more, in the backlight of LCD TVs, 1000w LED grow light are used, but also densely arranged. In order to be short, small and light, the available heat dissipation design space on the back is more restricted, and it should not be seen if high standards are required. Use a cooling fan, because the noise of the fan will affect the taste and mood of TV watching.

What are the side effects if the heat dissipation problem is not solved?

it is good! If the heat dissipation problem is not solved, and the heat of the LED cannot be dissipated, and the working temperature of the LED rises, will there be any impact? There are two main influences on this: (1) the luminous brightness is weakened, and (2) the service life is attenuated. For example, when the pn junction temperature (JuncTIon Temperature) of the LED is 25°C (typical working temperature), the brightness is 100, and when the temperature rises to 75°C, the brightness is reduced to 80, and when the temperature is 125°C, 60 is left to 175. Only 40 is left at ℃. Obviously, the junction temperature and the luminous brightness are inversely proportional to the linear relationship. The higher the temperature, the darker the LED brightness.

it is good! If the heat dissipation problem is not solved, and the heat of the LED cannot be dissipated, and the working temperature of the LED rises, will there be any impact? There are two main influences on this: (1) the luminous brightness is weakened, and (2) the service life is attenuated. For example, when the pn junction temperature (JuncTIon Temperature) of the LED is 25°C (typical working temperature), the brightness is 100, and when the temperature rises to 75°C, the brightness is reduced to 80, and when the temperature is 125°C, 60 is left to 175. Only 40 is left at ℃. Obviously, the junction temperature and the luminous brightness are inversely proportional to the linear relationship. The higher the temperature, the darker the LED brightness.

The effect of temperature on the brightness is linear, but the effect on the life is exponential. The same is based on the junction temperature. If the temperature is kept below 50 ℃, 1000w LED grow light has a life of nearly 20,000 hours, and only 75 ℃. For 10,000 hours, 5,000 hours remain at 100°C, 2,000 hours remain at 125°C, and 1,000 hours remain at 150°C. The temperature light changes from 50°C to 100°C twice, and the service life shrinks from 20,000 hours to 1/4 times 5,000 hours, which is extremely harmful.